Product Focus

by Stacy BriscoeProduct Focus

January 2019Product Focus: Evolution of the Basket Press

Comstock Wines in Healdsburg, Calif., is one of Sonoma County’s newer wineries, having opened its doors

just three years ago, in Au¬gust 2015. But Bob and Sandy Comstock had been selling grapes for well over a decade from their family vineyard near Geyserville, Calif., and it’s from that personal estate that the two began their winemaking venture.

Today, the couple owns a 20-acre vineyard along Dry Creek Road, which also includes a 21,000-square-foot facility, featuring a large tank room, multiple barrel rooms, a lab, cold room, crush pad and, of course, hospitality areas. Yet, despite all the state-of-the-art, mod¬ern equipment that adorns the winery permit¬ted to produce 35,000 cases a year, there sits in the corner a memory of simpler times.

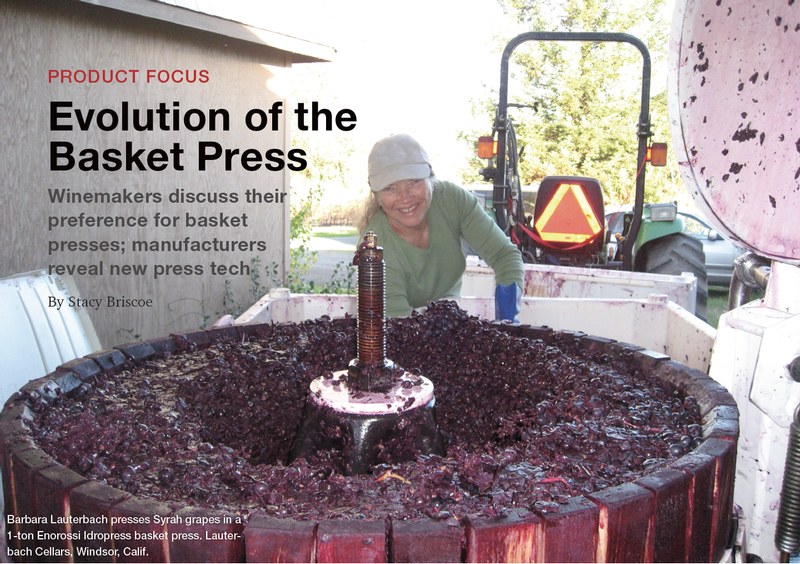

Meet Bertha. She’s the Comstocks’ original press, an Enorossi Idropress basket press. She can press no more than 1 ton at a time and produces 70% less juice than the winery’s newer Puleo SF-50 open drain membrane press. Bertha’s more of an inside joke than a serious piece of winemaking equipment. Though she’s so-named because she was, in fact, the largest piece of winemaking equip¬ment the Comstocks had in their basement-turned-winery just 15 years ago, she’s now one of the smallest in their new facility and used only for a select few pressing jobs.

But talk to Comstock’s winemaker, Chris

READ MORE »

Product Focus

November 2018Forming a Solid Foundation

Regular splashes of acidic solution, constant foot traffic, the weight and movement of heavy equipment and the repetitive use of cleaning chemicals — these are just some of the high demands literally placed on top of a winery’s floor. Whether reconstructing an existing space or designing a new build, the choice of flooring is one that impacts safety, sanitation and aesthetics.

READ MORE »

Product Focus

September 2018Forklifts

Cary Roulet, vice president of material handling for Holt of California, a company that provides forklifts for some of the largest wineries in the industry, says that regular maintenance and pre-season inspections are so important that Holt mechanics will run checks on machines regardless of where they were purchased. "Nothing takes the air out of a small startup winery than a machine that doesn't work," he said, adding that his crew will also pre-inspect any used machine a winery is considering purchasing.

READ MORE »

Product Focus

August 2018Automating Cork Quality Control

At one of Silver Oak Cellars' release-day parties in 2008, the winery had dug out a 6-liter bottle of Alexander Valley Cabernet Sauvignon from its library.

READ MORE »

Product Focus

July 2018Glasswashers for Tasting Rooms

Alex Lewis, director of hospitality at Testarossa Winery in Los Gatos, Calif., has been working in the winery's hospitality department for more than 11 years and says the glasswasher is one of the winery's most important pieces of equipment. "Because we are showcasing world-class wines, we are diligent about our glassware," she said. The historic winery is home to a tasting room and wine bar and plays host to a wide variety of events - from intimate tastings to weddings, and even wine education courses. "On a busy Saturday, we could easily require 1,750 glasses between all departments just for that day."

READ MORE »

Product Focus

May 2018Tools in Cap Management

Lee Miyamura has worked at Treasury Wine Estate's winery near Paso Robles, Calif., since 1990. In that time, the winemaker and her team have significantly expanded production while also seeking to improve operational efficiency.

The winery's fermentation tanks had originally been outfitted with air pumps dedicated for running pumpovers for red ferments. "As we kept expanding that necessitated us to look at different methods for managing fermentation," she said.

That included a look at using compressed air for tank mixing, although Miyamura said she had initially been concerned about it speeding up fermentation and being too extractive. Initial trials were followed by an investment in the air mixing technology and now Miyamura has plans to retrofit some tanks for the system. "I've come to find I have a preference for Pulsair during the fermentation process," she said.

Pulsair was one of the first companies to bring compressed air tank mixing to the wine industry and now offers a wide line of products to conduct "Pneumatage" or winemaking using the method. Air mixing has been one of the most significant advances in cap management and this Product Focus report will look at that and some other tools for more traditional cap management. Several suppliers, mostly European companies, manufacture tanks with a variety of ways to mix, wet or break up caps but that will be the focus of another report.

Air mixing turns tanks faster

READ MORE »

Product Focus

April 2018Oak Barrel Alternatives

Rather than just mimicking barrels or offering an affordable way to add oak impact, barrel-alternative suppliers are now selling products they claim provide an even greater degree of precision in terms of flavors and aromas to help winemakers achieve certain style characteristics. Several new products that debuted at the recent Unified Wine & Grape Symposium are designed to work with specific varietals, provide certain sensory notes or just get wines past the finish line and ready for bottling.

XTRACHÊNE

The new XtraPure and XtraVan oak chips by Xtrachêne are described by the French supplier as a "winemaker's best ally to protect must and wine from destructive oxidation." The French oak chips offer a high level of anti-oxidant capacity and receive a gentle heat treatment that makes them similar to untoasted oak. XtraVan chips add notes of vanilla and "extend generosity and roundness on the palate." The chips are produced with mainly French sessile oak and some American white oak, and are best used for long seasoning.

READ MORE »

Product Focus

March 2018New Barrels

Coopers continue to design new barrels to provide structure with less new oak impact. American oak suppliers also are offering more high-quality barrels built with staves that have undergone several years of seasoning and are sourced from specific forests. Other coopers are offering new toasts and wood types in 2018, and one supplier unveiled a new barrel specifically designed for high-alcohol wines produced in warmer, drier regions.

TONNELLERIE DE MERCUREY

Burgundian cooper Tonnellerie de Mercurey worked with its stave mill NT Bois and conducted a series of long-term tests with wineries in Bordeaux, California and Washington state to develop new toasts and oak selections for barrels to be used for Cabernet Sauvignon. The cooper’s M Prime barrel is an entirely new wood selection and toast intended to add “fullness and freshness” with a long, focused palate. The Haute Futaie selection is meant for wines of “great dimension and density” and is a good match for the cooperage’s light and long toast. Two other existing oak selections, Prestige and Nicolas, have also been updated with toasts meant for Cabernet. All of the toasts and oak selections are designed to “clean, lift, define and give real palate length.”

READ MORE »

Product Focus

February 2018Micro-Ox System

The use of precise oxygen additions to wine, juice or must has become a much more common practice at wineries as suppliers have expanded and improved their equipment. The most typical use remains micro-oxygenation to mimic barrel aging in tank with the release of a tiny amount of oxygen over time. Some of these systems can also be used as “macro-oxygenation” during primary fermentation.

JUCLAS

READ MORE »

Product Focus

January 2018Capsules: New decorative options help extend packaging strategy to entire bottle

The capsule at the top of a bottle is a valuable piece of real estate for brand managers to develop as part of the overall appearance of a bottle of wine. New printing techniques, colors and materials can help the top of the bottle match the label for stand-out presence on the shelf.

Stelvin

READ MORE »

Product Focus

December 2017New Oak Fermentors

In addition to concrete and stainless steel, oak remains a popular pick for fermentation Wines & Vines checked with cooperages to see what’s new in large-format oak vats and other oak containers designed for fermentation. Several coopers offer custom-built casks and foudres, and others have introduced oak fermentors in unique shapes or with special features. Prices vary depending on tank or cask size, quantity and shipping destination.

Seguin Moreau

READ MORE »

Product Focus

November 2017Barrel Racks

Fermentation and seismic safety are the two main areas in which barrel rack manufacturers are innovating. Suppliers have added new rack types and features to either make it easier to assist barrel fermentation or help keep barrel racks standing in the event of an earthquake. Wines & Vines checked with major suppliers about new and existing products.

Worksafe Technologies

READ MORE »

Product Focus

October 2017New Bottling Equipment

Wines & Vines checked with bottling line suppliers to see what new equipment is available or just debuted in the North American market for all stages

READ MORE »

Product Focus

September 2017New Wine Stoppers

The closures market is becoming even more competitive as suppliers release more products they claim offer consistent performance, are more sustainable and guaranteed free of any contaminant compounds. The following cork products and a new type of synthetic closure either launched or debuted in the North American market recently. Another major area of closure innovation, automated systems to ensure cork quality, will be the subject of an upcoming Product Focus feature by Wines & Vines.

READ MORE »

Product Focus

July 2017Winemaking Software

A wide range of suppliers now offer software systems specifically designed to manage and track winemaking operations. The subject was covered in detail by winemaker and contributing writer Richard Carey in the July 2015 issue of Wines & Vines. Since that feature was published, a few other suppliers have entered the marketplace, and some long-time vendors have updated their services. Some suppliers offer everything from a basic winemaking system that can later be complemented with modules for other operations to a complete winemaking system.

WINEMAKER’S DATABASE

READ MORE »

Product Focus

July 2017Membrane Filtration

Clarification of wine has undergone a revolution during the past couple of decades, and membrane technology has led that revolution. The technology of the systems and membranes have significantly improved due to the specificity of what and how grape components are removed from the liquid delivered to the winery. For some wineries, it starts with the juice, but more often it starts with the wine. There is no one system that provides all types of membrane separation.

The following list includes suppliers with widely varying system designs and operating parameters. This information should provide readers with a quick overview of wine industry membrane suppliers. Every winery can make better wine if they have access to membrane technology. If you don’t have the budget to buy one, you can hire a service; some services will ask that you take your wine to them, but most will come to your winery.

Richard Carey, Ph.D., is a wine consultant in Lancaster, Pa., and owner of Tamanend Wine Inc. He wrote a software program to help small wineries keep track of their wine production records and results of laboratory analyses.

VA FILTRATION USA

READ MORE »

Product Focus

June 2017Membrane Filtration

Membrane filtration has become a major factor in current winemaking production. Because of the breadth of the topic, this Product Focus about current uses of membranes for wine production will be broken into two parts. This first part reviews the major classifications of membrane usage and their efficacy in the wine-production process and includes a list of the companies that supply equipment. In the second part, we will provide information about the different membrane companies and their specific equipment for use in the wine-production process.

My first exposure to membrane technology took place in 1983 or 1984. Peter Meier from Millipore came to my winery in California to demonstrate the “greatest advent of high-tech equipment for the wine industry.” He brought a demo unit to show me visually what membranes can do. We ran a recently fermented wine through his new device and got a drip, drip, drip of pristinely clear, wonderful wine out the delivery side of the filter.

That event stimulated my continuing interest in this technology. Today membrane technology has evolved and now covers a wide range of processes, from primary fermentation to molecular sieving of good and bad molecules in the almost finished wine.

Membrane filtration is not quite at the magical level in wine production, but it is not that far off. Consider the following: The device can clarify a recently fermented, racked wine to 0.2µ in one step. After that, the same technology can remove volatile acids, and then even remove the ethanol to a point where the “wine” produced is alcohol-free. It is also possible to remove selected compounds based on molecular size and, after that, select molecules based on hydrophobicity versus hydrophilicity. One of the more bizarre aspects of membrane technology is its ability to select compounds based upon their chiral orientation (two compounds that differ based upon their mirror image).

The membranes can separate compounds over a wide range of molecular weights and charges. One can find companies such as VA Filtration, Pall and Koch Membranes that cover the whole gamut of membrane types, configurations and sizes of systems. There are also companies such as Oenodia (Stars electrodialysis/Bipolar), Romfil (microfiltration) or ATP Group (microfiltration) that specialize in one type of system.

The basic membrane filtration process

READ MORE »

Product Focus

May 2017Mechanical Grape Harvesters

With all of the features available in the latest generation of mechanical harvesters, the winery crush pad is essentially operating on wheels. Most suppliers now offer onboard destemming and sorting, meaning their customers’ days of receiving bins filled with smashed clusters, MOG and sprinkler heads are long gone. The machines featured here all come with destemmers and sorting systems standard, or they are offered as optional add-on equipment. Most machines collect harvested and sorted grapes into large bins that are then dumped into gondolas or half-ton bins, but a few can also be configured with a side discharge conveyor that empties into bins being pulled by a tractor running alongside the harvester (see photo above). Some suppliers also sell harvesters with sorting and destemming systems that can be towed by a tractor. It’s important to check with manufacturers to see if your vineyard works with harvesting and other functions such as mowing and spraying, which the machines are capable of performing. Cross arms and quad trellising, for example, don’t do well with mechanization. The machines are not cheap and start around $300,000, but vineyard managers who have made the investment can set pick dates and times with certainty, and that alone may be worth the cost.

READ MORE »

Product Focus

April 2017Product Focus: New Yeast Products

Wines & Vines checked in with manufacturers and distributors of yeast strains, yeast-derived products and other microbiological agents to learn about some of their latest offerings. Suppliers are offering more hybrid yeasts, vineyard isolates and nutrients to ensure steady and successful fermentations.

Lallemand

READ MORE »

Product Focus

March 2017Product Focus: New Barrels

Coopers continue to tout new barrels that provide subtle hints of oak and structure to wine. Examples include T.W. Boswell’s Minerality barrel and the latest edition to Seguin Moreau’s Icône line of barrels. Two other suppliers, Bouchard Cooperages and Tonnellerie Ô, are now offering American oak barrels built with wood from forests in specific states and even cut at specific stave mills.

T.W. BOSWELL

READ MORE »