|

|

PRINT » |

|

|

E-MAIL THIS PAGE » |

|

|

CLOSE THIS WINDOW » |

Uninoculated Fermentation

New insight into a traditional technique

Interest in uninoculated primary fermentation is increasing in wineries around the globe. This trend has various drivers including consumer preference for a perceived “natural” product and quality considerations. The latter motivation is likely the most significant, as research from institutions around the world highlights the potential positive impacts of vineyard- and winery-associated non-Saccharomyces yeasts (or wild yeasts) on the flavor, aroma and perceived complexity of the wines produced.

Interest in uninoculated primary fermentation is increasing in wineries around the globe. This trend has various drivers including consumer preference for a perceived “natural” product and quality considerations. The latter motivation is likely the most significant, as research from institutions around the world highlights the potential positive impacts of vineyard- and winery-associated non-Saccharomyces yeasts (or wild yeasts) on the flavor, aroma and perceived complexity of the wines produced.

Research at the Institute for Wine Biotechnology at Stellenbosch University, South Africa, has demonstrated the ability of several non-Saccharomyces yeasts isolated from a local vineyard to reduce wine ethanol levels by up to 1.5% and produce higher concentrations of desirable aromatics such as esters and monoterpenes.1

One important concept is that of “microbial terroir,” a term now fully entrenched in the wine dictionary. Until fairly recently, the potential contribution of microbes such as yeast and bacteria to terroir had been ignored.2

Recent studies (mostly in the past five years) have revealed that microbial populations contribute to the perceived geographic character and sensorial signatures of wines produced by fermentation with native-selection yeasts.3,4,5 Spontaneous fermentations are thus an ideal means to exploit the natural microbial biodiversity (unique in many ways) and enhance the regional identity of wines.6

There is a reason why yeast inoculation from dry active cultures of S. cerevisiae revolutionized winemaking in the first place: The risks associated with spoilage and stuck or sluggish fermentation in a spontaneous fermentation made controlled inoculation an attractive option for winemakers in the past. Fortunately, our understanding of non-Saccharomyces yeasts and ability to monitor and control fermentations have improved significantly over the years, affording today’s winemakers the best of both worlds: a predictable and successful fermentation outcome combined with the sensory complexity associated with spontaneous fermentation.

For winemakers considering a first foray into spontaneous fermentation, here are some helpful hints to guide you on your journey.

Quality is key

Compromised grapes may lead to a compromised spontaneous fermentation. If the quality of incoming grapes is questionable, pursue a safer inoculated fermentation (that would be to sequentially inoculate with commercial non-Saccharomyces yeast, then Saccharomyces yeast for risk mitigation and desired aroma profile).

Go easy on the SO2: Trying to start a spontaneous fermentation with a vineyard selection yeast by killing off most of the native species yeasts is probably not the best approach. Certain non-Saccharomyces yeasts are very sensitive to SO2 compared to S. cerevisiae. The anti-microbial effect of SO2 is greatly influenced by must pH.

It must also be kept in mind that some yeasts can form SO2 as a result of sulfate reduction and that residual vineyard sprays can have an effect on SO2 concentration in the must. Much less SO2 (than the norm of 30-50 ppm) or no addition is recommended for spontaneous fermentation. Working without SO2 brings new challenges to the winemaking process that must be carefully managed, such as potential oxidation and microbial spoilage.

Know your starting material

Not all musts are equal; some are less suitable for spontaneous fermentation than others. Most important is the initial sugar content of the grapes, as grapes harvested with extremely high sugar levels (above 24° Brix) could pose a high risk for stuck fermentation in the absence of sequential inoculation with a strong fermenting wine yeast strain. There are various reasons for this, but an important one is the lower alcohol tolerance of most species of non-Saccharomyces yeast. More sugar equals more alcohol, equals unhappy wild yeasts.

Juice that has been extensively clarified (less than 50 NTU) are likely to have a lower lipid and sterol content than musts with higher turbidity. In the absence of oxygen that stimulates ergosterol production by yeast, unsaturated fatty acids and sterols derived from grapes are essential to anaerobic yeast growth (2-4 mg/L phytosterols is required for maximal growth).8 They are particularly important in ensuring cell membrane integrity and fluidity (and thus yeast viability) in the face of increasing ethanol concentration.

Yeast nutrients with a high sterol and lipid content can be added to the must to enhance fermentation. The addition of oxygen to the must to stimulate ergosterol production could pose risks due to the low SO2 regime followed for spontaneous fermentation. However, oxygen additions during the rapid exponential growth phase of yeast is a reasonable option, as sufficient yeast growth and active biomass production means the yeast population present in the must will absorb most of the oxygen and remove it rapidly before oxidative reactions occur.

Another important consideration for spontaneous fermentation is pH, as high pH can influence the microbialpopulation and its proliferation in the must. Many spoilage bacteria are favored by high pH, especially some heterofermentative lactic acid bacteria (LAB).

Other aspects related to must composition (such as the availability of amino acids, specific lipids, vitamins and minerals) require further study. What we do know is that the nutrient requirements of many non-Saccharomyces yeasts are different than the traditional wine yeast strains of S. cerevisiae.

The most important (and simple) measurement to take is Brix, which will inform decision-making for or against a spontaneous fermentation. Choosing to continue with spontaneous fermentation of high-Brix must is not out of the question, but sequential inoculation with a commercial starter culture after an initial fermentation period is a safe recourse.

Skin contact: Skin contact is standard practice for red wines. For spontaneous fermentation of a white wine, it may be beneficial to allow some time for native yeast population to infuse the must after pr essing. Instead of sloshing a concentrated bucket of yeast paste into a tank, you are now relying on a film of yeast on grape skins to be released into the juice. A short incubation period (one or two hours) at 40° F after destemming and before pressing may increase the transfer of native species yeast from grape skins to must.

Know your microbes

Although this is not a feasible objective at present, consider this aspect when looking to the future: Not all winemakers have the privilege of knowing exactly which species of yeast and bacteria dwell in their vineyards, as these analyses are costly and require specialist services. Microbial populations also fluctuate over time and differ between vintages; they are strongly influenced by viticultural practices, especially vineyard sprays, regions and sub-regions.7

Cost-effective routine microbial diagnostics are on the horizon and primed to be a potentially transformational technology in the wine industry. Imagine being able to drop a sample of your crushed juice in a microfluidics chamber and out pops a list of the dominant microbial species in the juice. This would undoubtedly help to inform the decision whether or not to inoculate with a commercial strain as well as which fermentation strategy would enhance the impacts of desired strains present in the juice. Far from science fiction, this technology is primed to make its appearance in the next 10 years.

Keep a record of the outcomes (successful or not, problems experienced, etc.) of spontaneous fermentations conducted from your vineyards across different vintages to determine the suitability of your microbial terroir for spontaneous fermentation. Remember to practice good cellar hygiene to minimize the risk of unfavorable species influencing the outcomes of spontaneous fermentations in your cellar. Good cellar hygiene also limits primary inoculation to grape skin-borne yeast.

Patience required

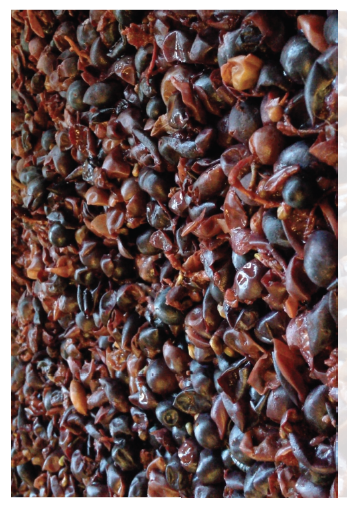

The species of non-Saccharomyces yeast that are naturally present on grapes at the highest numbers belong .png) mainly to the apiculate yeast genus Hanseniaspora (mainly Hanseniaspora uvarum teleomorph and Kloeckera apiculata) and other species of the genera Candida, Pichia, Kluyveromyces and Metschnikowia. These yeasts do not grow as strongly as the facultative aerobic yeast S. cerevisiae under oxygen-limited fermentative conditions.

mainly to the apiculate yeast genus Hanseniaspora (mainly Hanseniaspora uvarum teleomorph and Kloeckera apiculata) and other species of the genera Candida, Pichia, Kluyveromyces and Metschnikowia. These yeasts do not grow as strongly as the facultative aerobic yeast S. cerevisiae under oxygen-limited fermentative conditions.

Research has shown that even slight increases in dissolved oxygen in must can significantly increase the growth and persistence of non-Saccharomyces yeasts.9 Several practices employed during the first stages of winemaking such as pumping over, délestage or micro-oxygenation can increase O2 concentrations in grape must.

Oxygenation strategies in the early stages of both red and white wine fermentation will enhance the growth and impact of the native yeast species present. Controlling spoilage microbes prior to Saccharomyces dominance is very important. This is a very vulnerable phase, and smelling and tasting the must twice per day is recommended. It is also important to monitor volatile acidity.

Feed them well

When it comes to nutrition, primarily nitrogen supplementation, there is much that we still need to learn regarding non-Saccharomyces yeasts. One thing research has shown is that the amino acid requirements of yeasts differ greatly between species. Nutrients developed for cultured wine yeast strains may, in fact, not be optimal for different non-Saccharomyces yeast strains.

We do know that a certain population of yeasts are needed to complete an alcoholic fermentation. The addition of complex yeast nutrients—especially when the yeast assimilable nitrogen (YAN) is low—can stimulate yeast growth. Yeast nutrients that contain partially autolysed or fully inactive yeast is a good source of sterols, long-chain fatty acids, vitamins, minerals and some amino acids.

Specialized products are not yet available for non-Saccharomyces yeasts, and the best option is to apply the same supplementation strategies to spontaneous fermentation as one would for an inoculated fermentation. In other words, make sure that the must is not nitrogen-limited, especially higher sugar (above 23° Brix) musts.

Allow time for amino acid uptake before adding inorganic nitrogen (DAP)-containing nutrients, usually just before the end of the first third of fermentation. Proper yeast nutrition will go a long way to minimize the risk of a stuck fermentation. Keep a lookout for new products, though; it will not be long before suppliers meet the demand and create tailored nutrients for specific species of favorable non-Saccharomyces yeast for fermentation support.

Monitor very closely

Spontaneous ferments need more attention than inoculated fermentations. They require a certain level of coddling as there are more potential problems that may arise in the course of a fermentation.

The most important risk is the fermentation rate slowing down and even stopping prematurely, due to the fact that most non-Saccharomyces yeasts are slower fermenters (compared to S. cerevisiae) and less tolerant to the inhibiting conditions towards the middle and final stages of alcoholic fermentation.

In most spontaneous fermentations, S. cerevisiae naturally present (though initially at very low numbers) in the must will eventually dominate and complete the fermentation. If this progression does not occur, and warning signs of a slowing fermentation appear, it becomes necessary to take remedial action immediately and rescue the must with a commercial wine yeast strain. If not, spoilage micro-organisms can start to proliferate and form off-odors such as volatile acidity (LAB) and vinyl and ethyl phenols (Brettanomyces).

The commercial yeast dosage added will depend on the level of residual sugar and alcohol concentration. It can be up to double the normal recommended dosage for an inoculated fermentation. The lower

the sugar and the higher the alcohol, the higher the yeast dosage needed to complete a fermentation.

It is important that commercial yeast is also gradually acclimatized to the alcohol level in sluggish wine before being introduced to the wine. A proper re-inoculation strategy should be followed, starting with full analytical analysis of the sluggish/stuck wine as well as detoxification with yeast hulls before re-inoculation with commercial yeast. It is important that the temperature is conducive to re-inoculation.

Conclusion

Spontaneous fermentations may be fashionable today, but the same risks still exist as in the past. Executing a successful spontaneous fermentation requires greater scientific knowledge compared to inoculated fermentation. While less intervention in the form of culture inoculations is required, the management of a spontaneous fermentation is more intensive and relies on a solid knowledge base regarding yeast management.

Research in the field of microbial diversity analysis, microbial interactions, nutrition and control of non-Saccharomyces yeasts at the Institute for Wine Biotechnology (Stellenbosch University) is ongoing and will assist winemakers to conduct spontaneous fermentations in an informed fashion.

While certain grape varieties, winemaking conditions, wine styles and price points lend themselves to spontaneous fermentations, there are also times when inoculation with a selected yeast culture remains the better option.

Debra Rossouw is a researcher in yeast molecular biology at Stellenbosch University (Institute for Wine Biotechnology). She works with S. cerevisiae, non-Saccharomyces yeasts and lactic acid bacteria. She is interested in microbial interactions, cell walls and flocculation as well as aroma metabolism.

References

Rossouw, D. and F.F. Bauer. 2016 »Exploring the phenotypic space of non-Saccharomyces wine yeast biodiversity.» Food Microbiology 55: 32-46.

Renouf, V., C. Miot-Sertier, P. Strehaiano, and A. Lonvaud-Funel. 2006 “The wine microbial consortium: a real terroir characteristic.” OENO One, 40(4), 209-216. doi:dx.doi.org/10.20870/oeno-one.2006.40.4.864

Setati, M.E, D. Jacobson, U-C Andong and F.F. Bauer. 2012 “The vineyard yeast microbiome, a mixed model microbial map.” PLoS One 7, e52609.

Knight, S., S. Klaere, B. Fedrizzi and M.R. Goddard. 2015 “Regional microbial signatures positively correlate with differential wine phenotypes: Evidence for a microbial aspect to terroir.” Scientific Reports 5, 14233 doi:10.1038/srep14233.

Bokulich, N.A., T.S. Collins C. Masarweh, G. Allen, H. Heymann S.E. Ebeler and D.A. Mills. 2016 “Associations among wine grape microbiome, metabolome, and fermentation behavior suggest microbial contribution to regional wine characteristics.” mBio 7(3):e00631-16. doi:10.1128/mBio.00631-16.

Jolly, N.P., C. Varela and I.S. Pretorius. 2013 “Not your ordinary yeast: non-Saccharomyces yeasts in wine production uncovered.” FEMS Yeast Research. dx.doi.org/10.1111/1567-1364.12111

Bagheri, B., F.F. Bauer and M.E. Setati. 2015 “The diversity and dynamics of indigenous yeast communities in grape must from vineyards employing different agronomic practices and their influence on wine fermentation.” South African J. of Enol. & Vit. dx.doi.org/10.21548/36-2-957

Casalta, E., A. Vernhet, J-M. Sablayrolles, C. Tesnière and J-M. Salmon. 2016 “Review: Characterization and role of grape solids during alcoholic fermentation under enological conditions.” Am. J. Enol. Vit. 67: 133-138.

Shekawat, K., F.F. Bauer and M.E. Setati. 2016 «Impact of oxygenation on the performance of three non-Saccharomyces yeasts in co-fermentation with Saccharomyces cerevisiae.» Applied Microbiology & Biotechnology DOI: 10.1007/s00253-016-8001-y.

|

|

PRINT » |

|

|

E-MAIL THIS ARTICLE » |

|

|

CLOSE THIS WINDOW » |